There aren’t many variables for a conventional industrial LED light fixture. LEDs, at least for the top 3-4 manufacturers worldwide, are more or less all the same, and the same can be said for power supplies. So what can be done to improve efficiency? The easiest way is to simply list it in the catalogs, as many do, reporting efficiencies of 140 or 150 lumens per W, which in reality refer only to the LEDs, without taking into account losses due to temperature, lenses, glass, and power supplies. These losses, when added together, range from 20% for simple fixtures without lenses and with power supplies directly connected to the mains, to 32-33% for fixtures equipped with lenses, glass, and power supplies with primary/secondary isolation (as common sense suggests). Another solution is to use low-power plastic LEDs, which are the most efficient but have a short life (20-30,000 hours with 30% flux loss). The third way is to create innovative products, like ours.

LUXLED offers you a lighting project as an initial approach. To do this, our technicians visit your industrial facilities, conduct dimensional and structural surveys, and, most importantly, use lux meters to assess your current lighting. Based on your manufacturing category, we develop a lighting project using both our own products and those from other manufacturers we believe are suitable for your environment. The goal is to offer you a lighting solution with the best ground-level uniformity, energy efficiency, and value for money.

Our own designed products

CH64 serie

Industrial pendant light, 60×60 cm, equipped with 64 silicone optics and ultra-bright LEDs, perfect for even the most extreme industrial environments. Available with or without autodimmer.

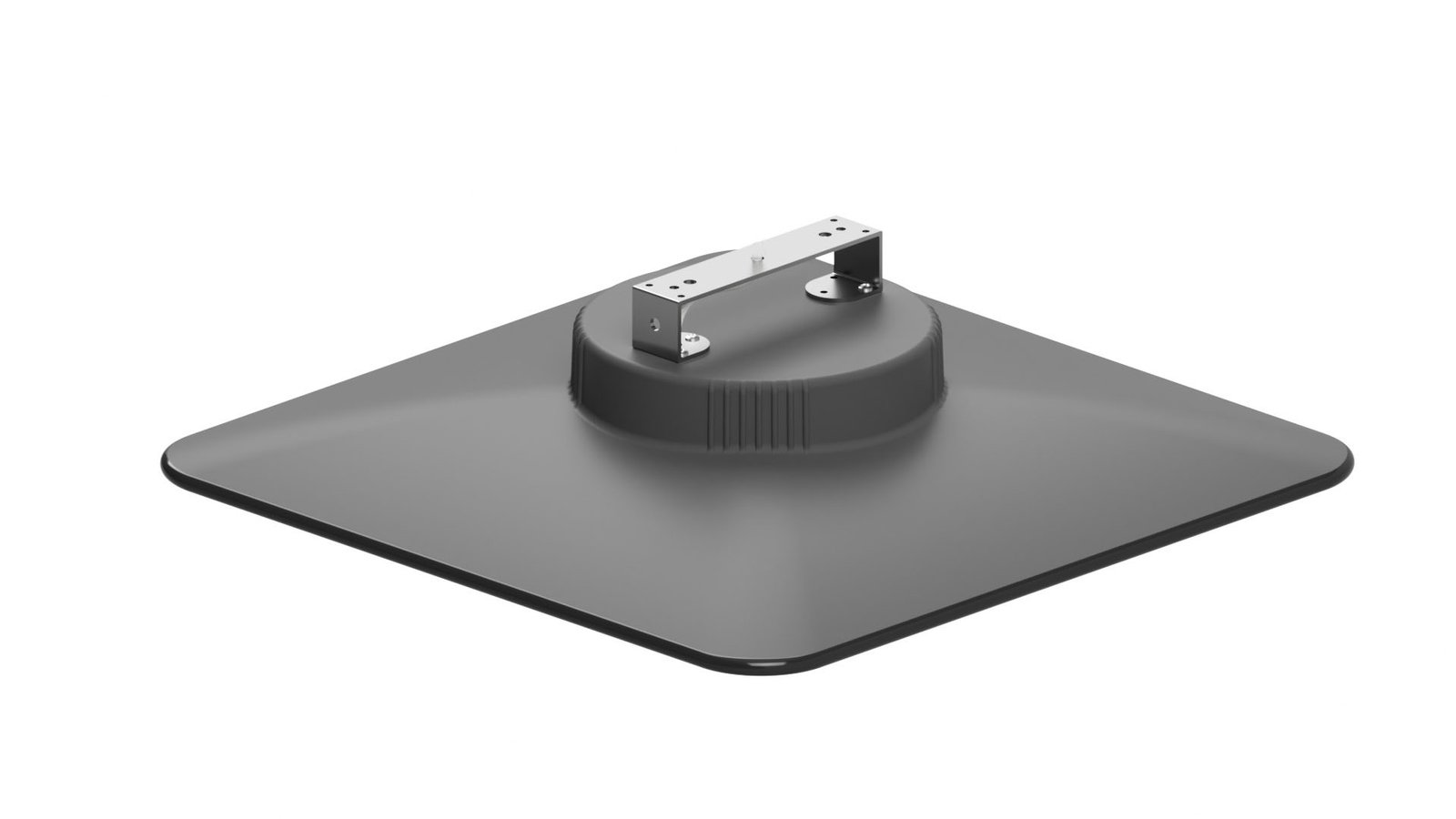

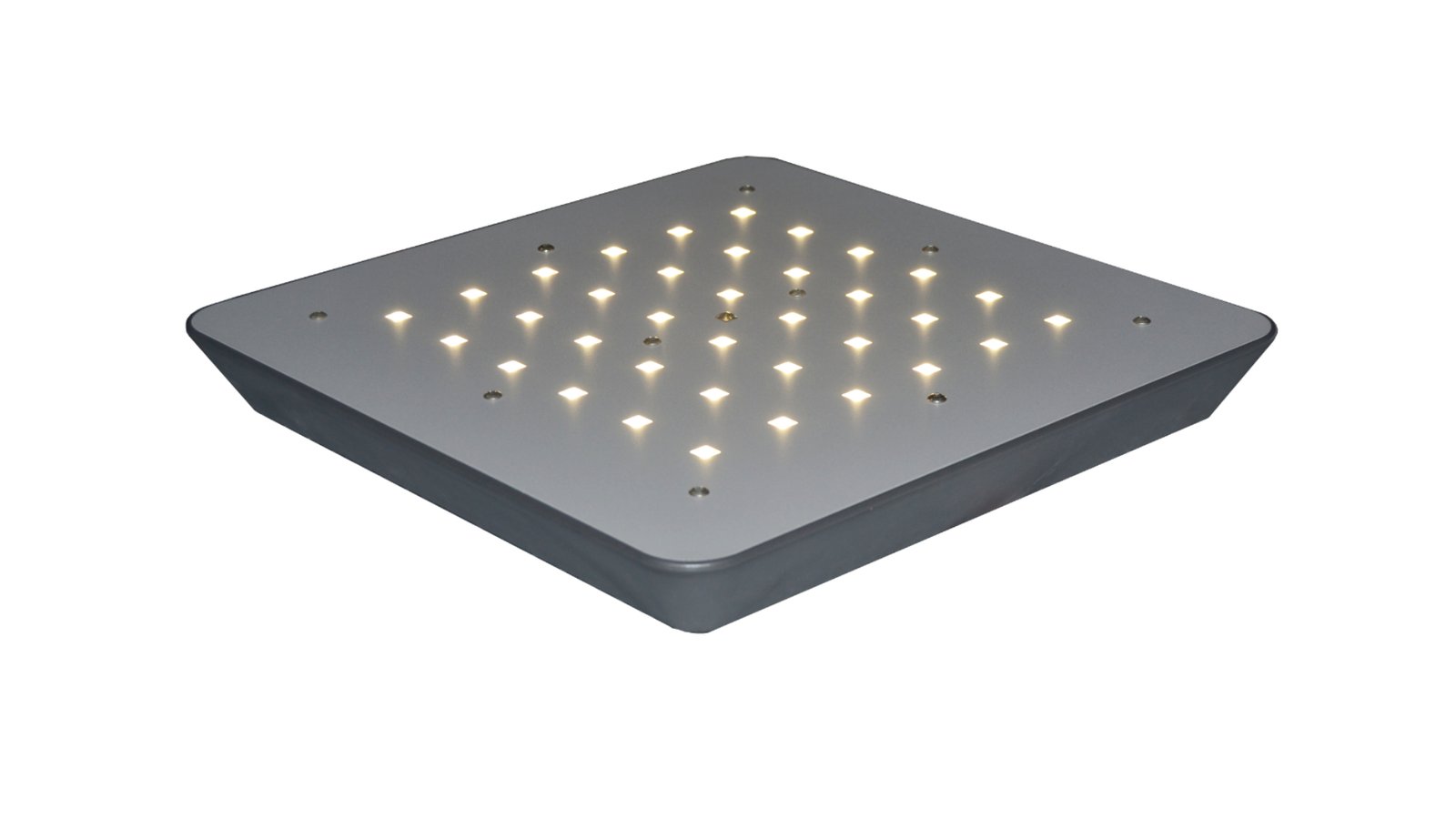

MY36 serie

Industrial ceiling light, 40×40 cm, equipped with 36 silicone optics, very high brightness LEDs, perfect for medium-sized industrial environments, laboratories, also installed close to the ceiling.